MIDDLESEX LTD

Why Choose Us?

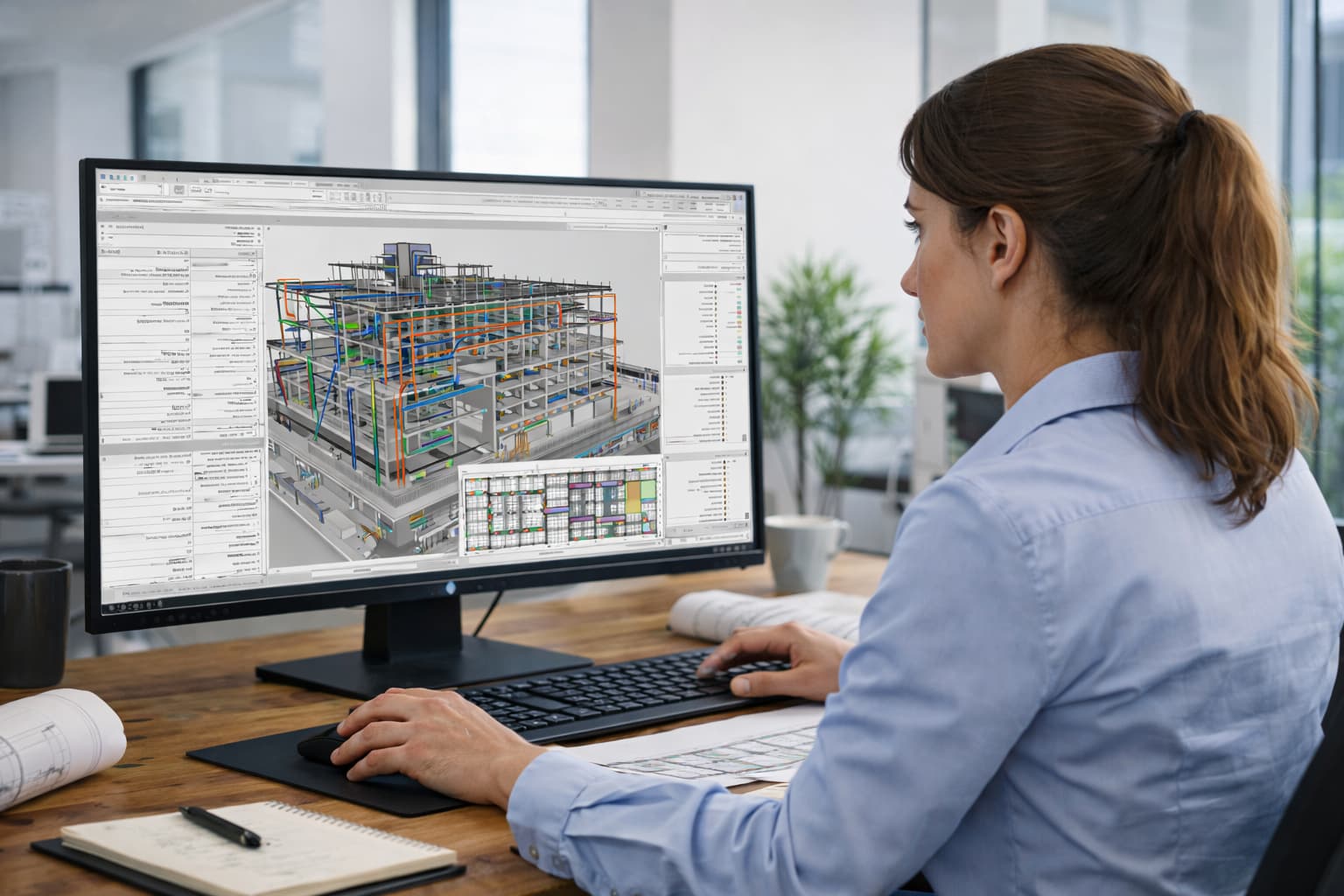

At Middlesex Dry Lining, every detail starts with design and ends with evidence. We partner with Tier 1 contractors and major developers to deliver partitions and ceilings that integrate seamlessly, with buildable detail agreed early, supervision sized to peaks, and one clean QA trail at handover. Our projects run quietly because they are planned, coordinated and proven from day one.