Metal Frame Ceilings – performing and non-performing

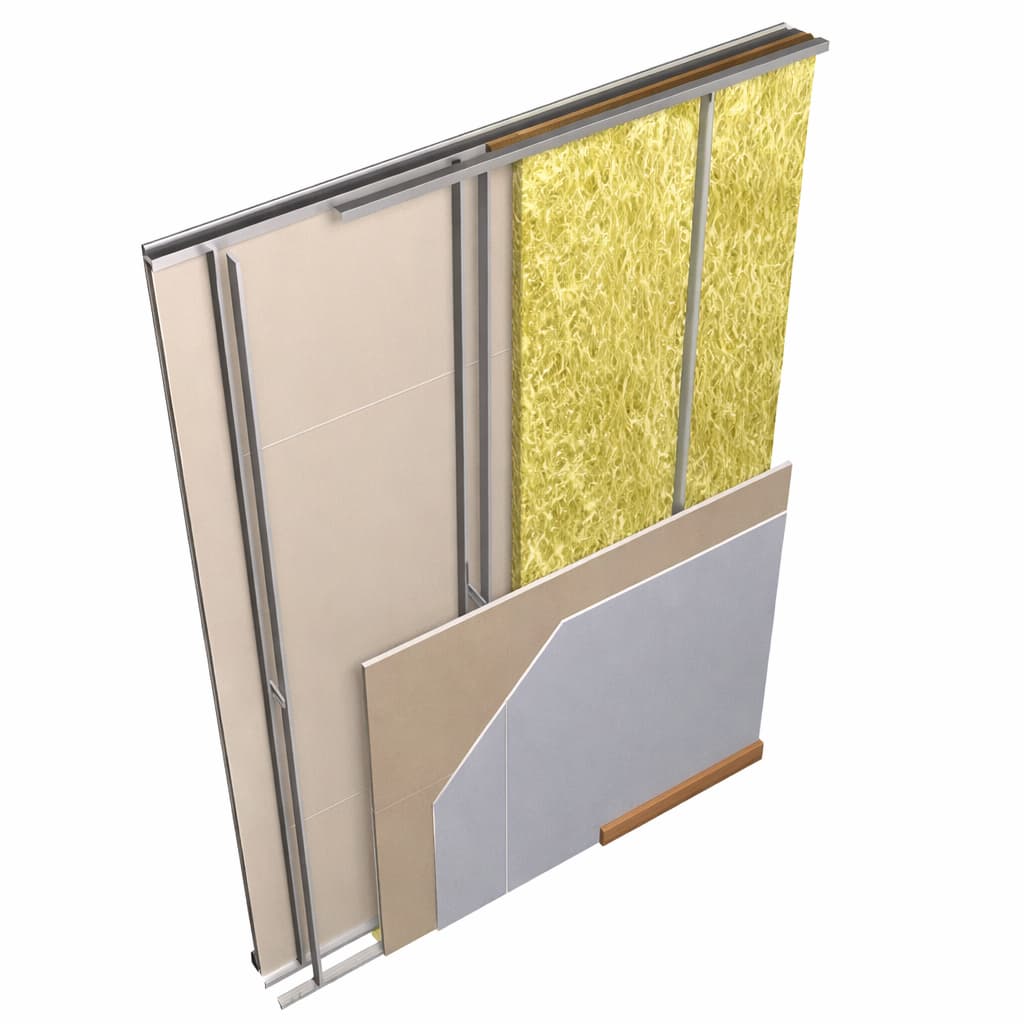

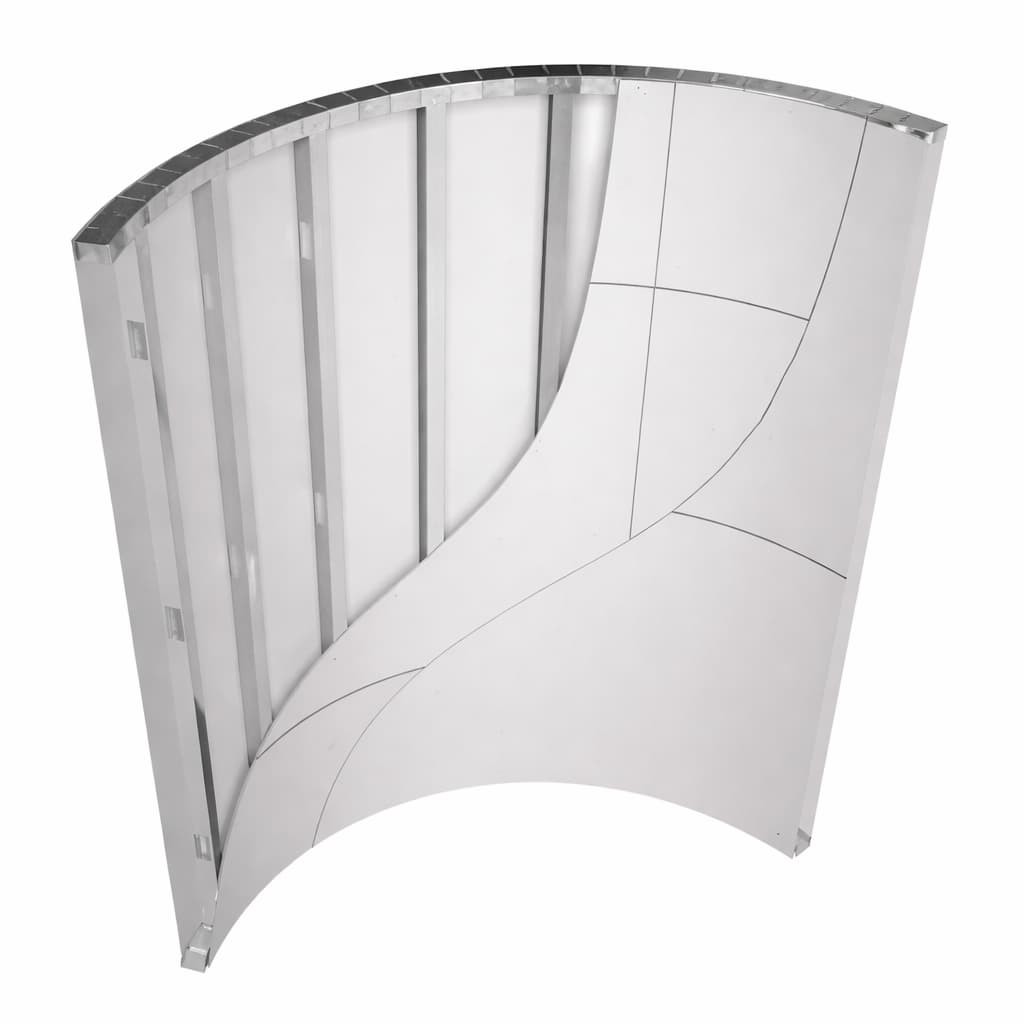

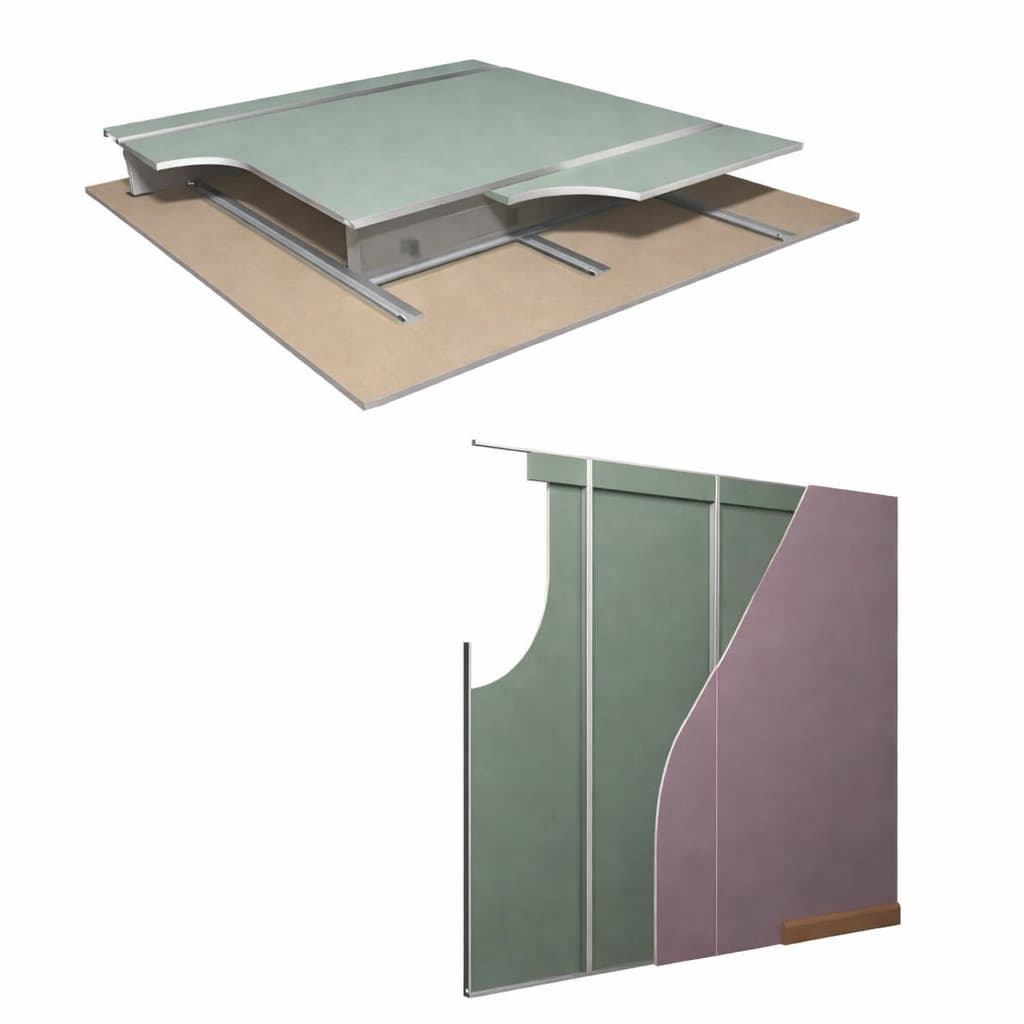

We install metal frame ceilings across office, healthcare and residential environments, including both performance-rated ceilings (for acoustic or fire resistance) and standard non-performing ceilings.

Design coordination: Our design team confirms ceiling zones, access requirements and service penetrations to ensure layouts align perfectly with lighting and mechanical services.

Programme alignment: Our in-house planner integrates ceiling works into the main contractor’s programme using Powerproject, with planned supervision and labour coverage for peak, night or restricted access periods.

Finish quality: Fix-first inspections and structured quality checklists ensure consistent finishes ready for decoration and fast client acceptance.

Outcomes: Ceiling installations that align with building services, achieve the specified performance and pass inspection first time.