MIDDLESEX LTD

Our Services

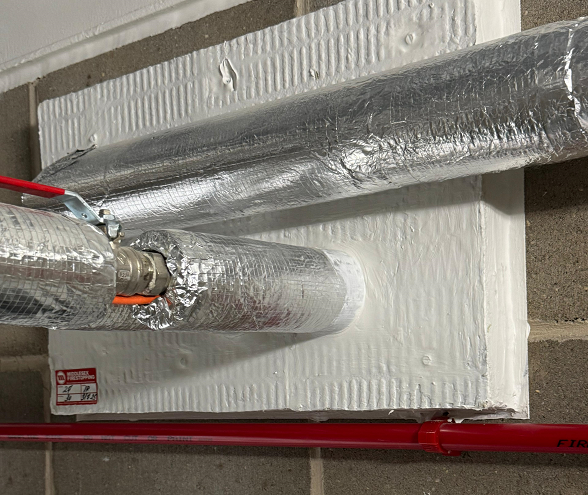

Middlesex Dry Lining delivers complete internal build solutions for Tier 1 contractors and developers, integrating design, installation and evidence based quality across every project. From partitions and ceilings to acoustic systems, finishing and fire protection, every service is delivered by in house teams under one accountable quality and programme framework.